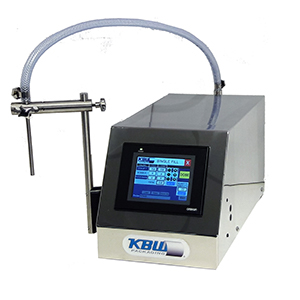

AF0015 Gear or Peristaltic Bottle Filling Machine

AF0015 Liquid / Bottle Filling Machine. is a small potable semi-automatic liquid filling machine.Uses Gear or Peristaltic filling machine technology. Its a cost effective small volumetric filler. For liquids and creams or essential oils with a single nozzle. It comes with a choice of gear pumps. Dependent on fill size or a peristaltic pump.The filler is operated as a continuous / Single fill or a timed fill. In contrast it has the ability of stage filling. Using accurate and repeatable servo filling technology with a touchscreen. Therefore ease of use and the ability to store recipes.

AF 0015 Premium Single Head Gear or Peristaltic Bottle Filling Machine

Its primarily used in the cosmetic including toiletries. Alternatively household as well as pharmaceutical markets. By companies with small to medium scale production runs. It has been used for all sorts of other applications so please ask about yours. The product to be filled is drawn up a hose by a gear pump or Peristaltic pump. Easily making a Gear or Peristaltic Filling Machine giving you a multi functional machine. You can set the amount to be filled on the touch screen display. The liquid filling machine can be used for liquid products from shampoo to E Liquid including creams.

Operation

The AF 0015 bottle filling machine is operated using a 5.6″ HMI Colour Touchscreen, including Recipe Management, with up to 20 recipes. The operator may adjust the liquid product dose including the flow rate, (pump speed) in operation. Firstly Single Dose and Secondly Multi Dose Fill can be selected. Thirdly with Clean in Place In conclusion Continuous functionality.

The machine fills to a predetermined count value. Then on reaching the correct value of pulses the pump head control stops and the filling cycle is complete. The operator changes the containers over manually. Then initiates the next filling cycle using either an optional foot switch. Or by either pressing the dose button in Single Fill or the pre-set time delay in Multi Fill.

Fill volumes from 5 ml to 5 Litres with filling accuracy and repeat-ability greater than +/- 0.5%. Please Note on the Peristaltic filling machine option then fill volumes can be smaller than the 5ml stated.

The AF 0015 Liquid / Bottle Filling Machine comes pre-configured for a pneumatic nozzle. With the emphasis on simple operation including tool free contact parts.

AF0015 Bottle Filling Machine Features

AF 0015

- Servo controlled accurate product dosing and pump speed adjustment.

- 5.6″ HMI Colour Touch Screen including Recipe Management.

- 5 ml to 5 Litre Fill volumes.

- Accurate dispensing with excellent repeat-ability.

- Customers can adjust Fill Volume (Dose) and Product Flow (pump speed) during operation.

- Single Dose operation also including Multi Dose filling modes.

- Two speed pump control for shaped containers.

- Clean in Place (CIP) functionality.

- Simple operation with fast product change-over.

- Complete Nozzle range to suit all Filling medias.

- Pre-configured for the use of Positive Shut-off Pneumatic Nozzles.

- Tool free removable product contact parts.

- Options available for filling high viscosity products such as creams.

- Quantity Filled displayed.

- Storage available for up to 20 recipes.

- 1.5 L, 6 L, 10 L and 20 L pump options.

- Peristaltic Pump Option

- Nozzle position to the left, as standard, additionally, as Option to the right.

- Pre-configured Multi-pole or RF coax connection for Foot Switch or Integration of third party equipment.

- Visual back seal fault recognition slot and chamber.

- Small machine footprint.

- Constructed in compliance with FDA approved materials.

- Optional full IQ/OQ Validation Support Documentation.

- Fast product changeovers.

As well as this Semi-Automatic single head Bottle Filling Machine see below the range we manufacture:

- A Peristaltic filling machine option is available. By Adding a Peristaltic Pump to the Machine.

- An Semi-Automatic 2 head liquid filling machine.

- Also a Automatic 2 head liquid filling machine.

- Another is a Automatic 4 head bottle filling machine.

- Furthermore, Automatic 6 or 8 head liquid filling machines.

- Finally in conclusion Automatic 10 or 12 head Bottle Filling Machine.