Are you curious about how tablet counting machines work? As a leading packaging machine manufacturer in the UK, we are here to give you an exclusive behind-the-scenes look. Tablet counting machines are crucial in the packaging process. By understanding how they work, you can optimize your production line.

In this article, we’ll explore the process, the types of tablet counting machines, the components involved, and the benefits of using them. So, let’s dive in!

The Working Principle of a Tablet Counting Machine

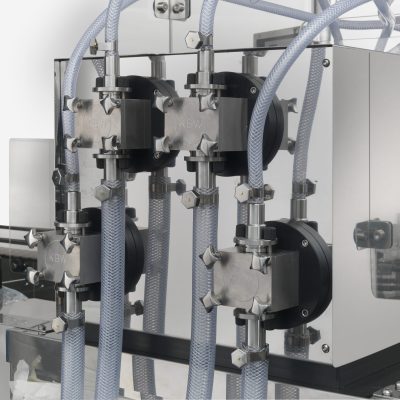

Tablet counting machines use vibration and gravity to achieve precise counting. The machine has a hopper or reservoir at the top. At the bottom, you will find a vibrating disk and sensors with pockets or cells. Tablets fall from the hopper into the cells on the vibrating bowl.

Firstly, the basic principle involves a vibratory disk separating and counting tablets, capsules, and other small objects. An electric motor drives the disk, creating a vibratory motion. This motion separates the objects and forms single files. Then, as the objects pass through the bowl, infra-red beam sensors count them. The number is displayed on a screen. Once the correct number of tablets is reached, the machine releases them into a container.

Here is the step-by-step process:

- Set the tablet count: You set the desired tablet count.

- Load the tablets: Load the tablets into a hopper at the top of the machine.

- Tablet movement: The tablets fall through a chute into a vibrating disk.

- Counting process: The tablets funnel through a series of sensors that determine the size, shape, and count of the tablets.

- Dispensing: As the tablets pass through the sensors, the machine counts and dispenses them into the appropriate packaging container.

In general, all tablet counting machines operate on similar principles. However, there are variations depending on the type and model.

Types of Tablet Counting Machines

Tablet counting machines come in various sizes and styles to meet different needs. They can be either semi-automatic or fully automatic.

Semi-Automatic Tablet Counting Machines: These portable machines are ideal for small-batch production. For instance, the AC 500 and AC 1000 tablet counters can handle up to 1,000 tablets per minute. Thus, they are perfect for pharmacies.

Fully Automatic Tablet Counting Machines: These machines are designed for industrial use. They have outputs ranging from 4,000 to 6,000 tablets per minute. For example, the AC 4000 Tablet Counter handles up to 4,000 tablets per minute. Therefore, it is suitable for large-scale production. Additionally, automatic counters offer more functionality than their semi-automatic counterparts.

Benefits of Using Tablet Counting Machines

Firstly, tablet counting machines guarantee precise counts. With preset specifications and precision settings, you can rest assured your tablets will be correctly counted and packaged.

Moreover, these machines save time and labor costs due to their mostly automated nature. This efficiency allows you to get your products out the door faster.

Furthermore, consistent product quality is ensured. By using a tablet counting machine, you virtually eliminate mistakes associated with manual counting.

In short, tablet counting machines provide accuracy, speed, consistency, and cost savings. Therefore, they are an ideal choice for businesses looking to increase efficiency and streamline processes.

Get Reliable Tablet Counting Machines in the UK

When selecting a tablet counter, consider factors such as accuracy, speed, noise level, weight handling capacity, power consumption, safety features, ease of operation, and maintenance requirements. These factors will help you choose the best tablet counter for your needs.

As an industry leader in packaging machinery, we want you to see the value and enjoy your purchase. To start your search on the right footing, visit KBW Packaging LTD. Choose from among the best tablet counting machines in the UK. Contact us now for purchases or consultations.