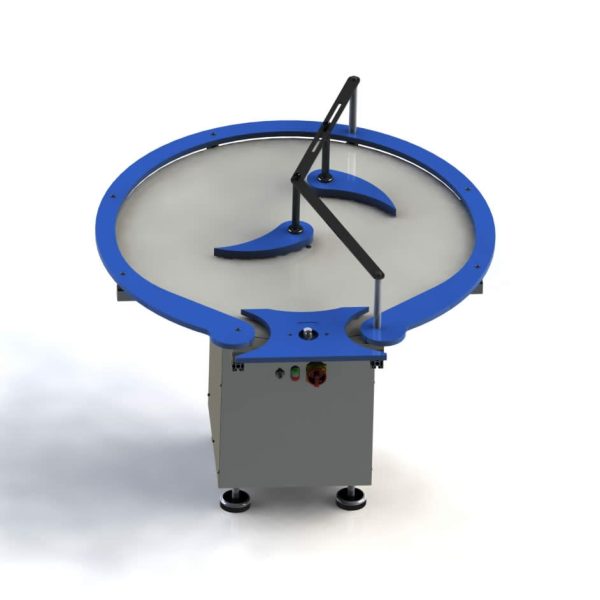

Large Capacity Central Buffer Table

The large capacity Central Buffer Table is essential for efficiently collecting products, ensuring a seamless workflow. Moreover, it effectively manages the flow of products, contributing significantly to the overall efficiency of your production line.

Inverter Controlled Variable Speed Drive

Furthermore, the table features an inverter-controlled variable speed drive, allowing for precise speed adjustments. This enhances the flexibility and efficiency of your packaging process. Additionally, you can easily modify the speed to match your production requirements.

Tool-less Design for Fast Product Changeovers

Additionally, the table boasts a tool-less design, enabling quick product changeovers. This feature reduces downtime and boosts productivity by simplifying the changeover process. Consequently, you can switch between products swiftly without the need for tools, streamlining operations.

Simple Operation of Central Buffer Table

Moreover, the table is designed for simple operation. Its user-friendly interface enables staff to operate it effortlessly, minimizing training time and potential errors. This ensures your team can maintain high production standards without complications.

Hygienic Design Using FDA Approved Materials

Finally, the table is constructed with a hygienic design using FDA-approved materials. This ensures compliance with the highest cleanliness and safety standards, making it suitable for food and pharmaceutical industries. The hygienic design maintains product integrity and adheres to health regulations.

Explore More from KBW Packaging

To further optimize your production line, explore KBW Packaging’s extensive range of complementary equipment. Our selection includes advanced liquid filling machines, capping machines, labeling machines, and unscrambling tables, all meticulously designed to ensure a seamless and efficient production process.

Liquid Filling Machines

Our liquid filling machines are engineered for precision and reliability, catering to various liquid viscosities and container types with consistent accuracy.

Capping Machines

- Press Capping Machines: Ideal for securing press-on caps with precision and reliability.

- Screw Capping Machines: Perfect for applying screw caps, ensuring tight seals and preventing leaks.

- ROPP Capping Machines: Specifically designed for Roll-On Pilfer-Proof caps, providing tamper-evident sealing for enhanced security.

Labeling Machines

- Round Labeling Machines: Efficiently apply labels to round containers, ensuring uniformity and accuracy.

- Top, Bottom, and Side Labeling Machines: Versatile labeling solutions for applying labels on various parts of products, catering to diverse packaging needs.

Unscrambling Tables and Outfeed Collection Table

Furthermore, our unscrambling tables ensure a smooth product flow into the production line. This aids in maintaining efficiency and minimizing downtime, contributing to a streamlined operation. Together with the outfeed collection table, these tables ensure a consistent and organized workflow.

Seamless and Efficient Production Process

By integrating these advanced solutions into your production line, you can transition to automation seamlessly. This comprehensive selection enhances productivity, ensuring accuracy and consistency in your operations. Our equipment combination creates a smooth workflow, optimizing overall production efficiency.

Personalized Advice from KBW Team

For tailored advice on the best solutions for your specific packaging needs, please contact a member of our KBW team. Our experts are dedicated to helping you find the perfect equipment to optimize your production process. Benefit from our expertise and discover how KBW Packaging can elevate your operations with high-quality, efficient, and reliable packaging solutions.