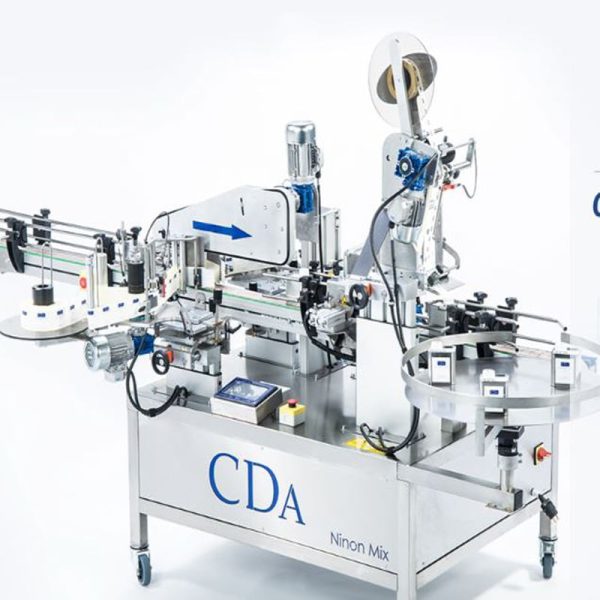

CDE 0018 (Ninon Mix 2500) Automatic Labelling Machine

The CDE 0018 (Ninon Mix) is an advanced automatic labelling machine designed for applying adhesive labels with precision. Its high-quality label applicators help in optimising the labelling process by reducing bottlenecks and improving placement accuracy. This versatile machine is capable of labelling square, cylindrical, oval, and tapered products on both the sides and top.

It can apply up to five labels at a rate of up to 41 products per minute. Additionally, its modular design allows for the addition of labelling stations as the customer’s product range evolves.

The automatic labelling machine accommodates products between 15 and 115 mm in size and features a user-friendly touch screen interface that can be integrated into a complete packaging line.

Why Choose the CDE 0018 Automatic Labelling Machine?

This automatic adhesive labelling machine stands out due to its ease of use, adaptability to various product types, and exceptional quality-to-price ratio. As a result, it has become one of the bestsellers in the CDA range, adopted by hundreds of companies across diverse industries such as cosmetics, pet care, pharmaceuticals, and toiletries.

It handles a wide array of products, including cream jars, massage oil bottles, perfume bottles, jam and marmalade jars, honey jars, vinegar bottles, oil bottles, solvent bottles, and detergent jars.

Key Features of this Fully Automatic Labelling Machine

- Motorized Conveyor: Equipped with a chain width of 82.6 mm.

- Cylindrical Labelling Station: Suitable for cylindrical products, with adjustable reel heights from 10 mm to 155 mm (standard).

- Adjustable Label Application Height: Controlled via the touch screen.

- Mandrel Sizes: Compatible with 40 mm and 76 mm mandrels for label rolls.

- Product Detection Cell: Triggers label application automatically.

- Pressure-Sensitive Cylinder: Labels products with diameters between 40 mm and 90 mm (standard).

- CE Certified: Ensures compliance with European safety standards.

- Power Consumption: Approximately 1 kW, depending on options.

- Quality Control: Features that minimize manual labour and ensure consistent product presentation, enhancing productivity and meeting various labelling requirements effectively.

Available Options

- Stainless-Steel Conveyor: Choice of chain widths: 82.6 mm, 114.3 mm, or 190.5 mm.

- Aluminium Profile Conveyor: With a 190 mm chain width (standard 82.6 mm).

- Lockage System: Options include double cylinder, guided cylinder, and selection screw.

- Second Cylindrical Station: Enhances labelling capacity.

- Riser for Cylindrical Posts: Accommodates coil heights up to 285 mm (standard is 155 mm).

- Automatic Aligner: Ensures precise product placement.

- Stabilizer Belt: Maintains consistent product speed.

- Flat Surface Labelling Station: Adaptable to coil heights from 10 mm to 155 mm (standard).

- Conical Product Labelling Station: Also adjustable for coil heights from 10 mm to 155 mm (standard).

- Top Labelling Station: Suitable for applying labels to the top of products.

- Removable Tray: For easy maintenance.

- Drive Roller Machining: Customizable for different product sizes.

- automatic labelling machine designed for applying adhesive labels with precision.

- This versatile machine is capable of labelling square, cylindrical, oval, and tapered products on both the sides and top.

- Accommodates products with a diameter of 700 mm.

- Marker/Coder: For applying DLCs, barcodes, etc.

- Scout Cell: Aligns labels on notches, handles, images, and welds.

- Ultrasonic Cell: Specifically for transparent labels.

Choosing the Right Automatic Labelling Machines

Selecting the right labelling machine involves considering several factors to ensure it meets your specific needs:

- Determine the type of product being labelled: Different labelling machines are designed for specific product types, such as cylindrical containers or flat surfaces.

- Consider the labelling speed required: Automatic labelling machines can apply labels at high speeds, making them ideal for large-scale operations, while semi-automatic machines may be more suitable for smaller production runs.

- Evaluate the level of customization needed: Some labelling machines offer customisation options to meet specific labelling needs, such as applying multiple labels or accommodating different label types.

Industry Applications for automatic labelling machines

The CDA Range of “Ninon” labelling machines is ideal for various industries, including cosmetics, toiletries, and food packaging. These machines efficiently label products such as shampoo, shower gel, liquid soap, cream, body oil, mouthwash, vinegar, oil, sauce, fruit juice, syrup, honey, jam, marmalade, mustard, detergent, solvent, motor oil, paint, and varnish.

Advantages of the CDE 0018 Labelling Machines

The Ninon Mix is designed for label rolls with a left outer winding direction on cylindrical and rear SIDE posts, while the front SIDE station accommodates rolls with an outer right winding.

The machine supports coil dimensions with a maximum chuck diameter of 76 mm, a maximum coil diameter of 260 mm (325 mm with the detachable tray option), and a maximum reel height of 155 mm (285 mm optional). The colour touchscreen facilitates the adjustment of various parameters, such as position selection, timeout settings, and data entry speeds (optional selection screw).

The cylindrical product labelling station operates with asynchronous motors and frequency inverters, ensuring precise label application. Can be added into a packaging Line either Tablet counting, Liquid filling or capping machinery.

The CDE 0018 labelling machinery is a versatile and reliable solution for businesses seeking efficient and adaptable labelling capabilities, guaranteeing accurate label placement every time. Its extensive range of features and options makes it suitable for a wide variety of products and industries, ensuring high-quality labelling solutions with top performance.

Labelling machines used in key industries with various sectors of activity such as:

- Pet Care

- Toiletry Industry

- Wine and Drinks

- Cosmetics

- Veterinary Pharmacy Industry

- Health Store and Food Packaging Industry

- Pharmaceutical Industry

- Nutraceutical Industry

- Fragrance and Essential Oils

Looking for labelling machines for your business? Feel free to reach out to our support team for further information to discuss your labelling project requirements and the custom solutions that we have on offer.

At KBW Packaging, we understand the importance of providing excellent customer support and service for our labelling machines. Our dedicated support team is available to assist with any queries or concerns, ensuring you get the most out of your labelling machinery.

By choosing KBW Packaging, you are not only investing in high-quality labelling machines but also in a support system that ensures your production process runs smoothly and efficiently.