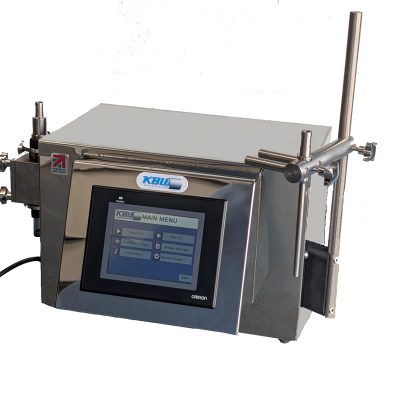

What is a Liquid Filling Machine

A liquid filling machine fills containers with liquid products efficiently, making it essential in industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals. These machines provide precise control systems, adjustable fill volumes, and quick changeover features, ensuring consistency in every operation. Whether you’re packaging liquid soap or pharmaceutical solutions, they deliver the accuracy needed to meet high production standards. As a result, they help maintain smooth and reliable operations across various industries.

Versatility Across Multiple Industries

In addition to their precision, KBW’s liquid filling machines are highly versatile. They serve a wide range of industries, from household products to industrial sectors. For example, they can easily adapt to packaging hand sanitizers, detergents, disinfectants, motor oils, and agricultural chemicals. This flexibility enables businesses to handle diverse packaging needs both efficiently and accurately. As a result, companies can meet a variety of demands with ease.

Ideal for the Cosmetic Industry

KBW’s liquid filling machines work especially well in the cosmetic industry. These machines efficiently package liquids, creams, shampoos, conditioners, body oils, and moisturizers with great precision. This helps cosmetic businesses uphold strict packaging standards while ensuring high-quality products consistently reach consumers without slowing down production.

Enhancing Productivity in Key Sectors

Our liquid filling machines boost productivity in industries like cosmetics, pharmaceuticals, household products, veterinary care, and food. With advanced filling heads, these liquid filling machines streamline operations, improving automation and efficiency. As a result, companies can produce more while maintaining product integrity, making it easier to meet their goals.

Comprehensive Packaging Solutions

When businesses choose KBW, they get equipment that boosts efficiency and ensures consistent product quality. Our liquid filling machines perform reliably, helping businesses streamline and improve their packaging processes with confidence.