The world of capping and sealing is complex. It possesses many nuances and granular details that can differentiate between sunk costs and found money.

Below, we’ll examine the topic of sealing bottle caps. Namely, we’ll explore the most efficient approaches to bottle cap sealing that serve your company, employees, and products best.

Why Should Sealing Your Bottle Caps Be A Top Priority?

Before delving into the how of the matter, it’s important to answer why you should prioritise bottle cap sealing.

All your work to make your product – no matter what that product is – falls by the wayside if your capping and sealing come up short. Customers won’t get their chance to use or consume whatever they’ve bought from you because of spills, leaks, or the inability to open your container. Or, perhaps an ineffective seal has impacted the freshness of your product.

An oversight like inadequate sealing processes doesn’t allow your product to distinguish itself. Instead, your company can suffer reputational damage despite your otherwise superior work.

How Are Bottle Caps Sealed?

The best and most straightforward approach for a company like yours is to use bottle-capping machines that best suit your production methods.

Finding the proper bottle-capping and sealing fit for your organisation depend on your products, procedures, layout, and employees. To that point, the correct capping machine for your company could be the wrong one for your competitor.

Depending on your business needs, you might require one (or more) of the following types of bottle-capping machinery:

- Press capping machinery

- Automatic capping machinery

- Semi-automatic capping machinery

- Screw capping machinery

Your final choice will require plenty of research and deliberation to maximise the value of your bottle-capping machinery investment.

Top Three Considerations When Purchasing Bottle Capping Machines

Below are the top three considerations you need to make before investing in bottle-capping machines:

1) What Types Of Caps Need Sealing?

Your company could need to seal caps, such as:

- ROPP

- Press

- Trigger

- Screw

Whichever type of cap requires sealing will dictate the type of sealing machinery you purchase.

2) How Complex Or Demanding Are Your Sealing Needs?

- Your capping needs could be relatively straightforward and require bench and tabletop machines that employ cap-tightening applications.

- Conversely, the demands of your capping might be far more elaborate and broader in scale, calling for cap place operations and fully automatic plugging.

- There’s always the chance you need something in between, in which case, perhaps a semi-automatic solution makes sense.

3) What Are The Ergonomic Needs Of Your Employees?

- Repetitive strain injuries and labour fatigue are problems you’re always looking to minimise in the workplace. You can do so with your choice of bottle-capping machine.

- For instance, The AK0002 Bench/Tabletop Screw Semi-Automatic Capping Machine has a range of inserts and chucks for various capsizes. This feature offers many ergonomic advantages, staving off injuries and fatigue.

Are you scouring the market for bottle-capping machines that best suit your production needs?

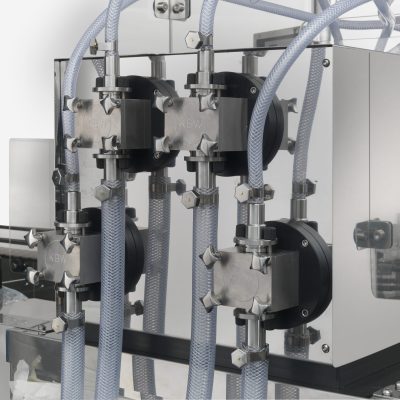

If so, KBW Packaging LTD’s cutting-edge bottle-capping machinery has a distinctive look. We offer options for screw cap tightening to your preferred toque, press-on caps, plug insertion, pump-action spray caps, trigger-spray caps, and more. Contact us today for a consultation.