How to decide on the most suitable liquid filling machine for you and your business

When you are looking to purchase, or lease purchase, your first, or next, liquid filling machine there are several interesting points to consider early in the process to make sure the machine you find best fits your liquid filling needs. Ultimately production rate demands versus the budget available are going to define the type of machine required and available but there also needs to be a consideration of factors such as the viscosity / consistency of the product you are looking to fill, the container or bottle type, as well as the ease of use and flexibility of the machine.

Viscosity / Consistency of Product

To be able to understand which liquid filling machine will be suitable for your product it is essential to understand the viscosity / consistency of the product that you wish to be filled into a container or bottle. Most machines will be capable of filling a semiviscous fluid, but a more specialised machine may be required if the fluid is of an extremely thick heavy viscous consistency. You will then need to consider how the product viscosity / consistency could also affect the filling rate you require and potentially look for a liquid filling machine that can offer a suitable filling rate balanced against the product viscosity.

Container or Bottle Type

The type, or types, of container or bottle that you are looking to fill will also need to be considered, to be able to understand which liquid filling machine will be suitable for your production. Most machines will be capable of handling and filling standard size and material of container or bottle, but a more specialised machine may be required to offer a complete nozzle range with the flexibility to fill a number of different containers or bottles whilst offering smooth and accurate container or bottle handling for more fragile or bespoke container or bottle materials, shapes and sizes.

Ease of Use and Flexibility

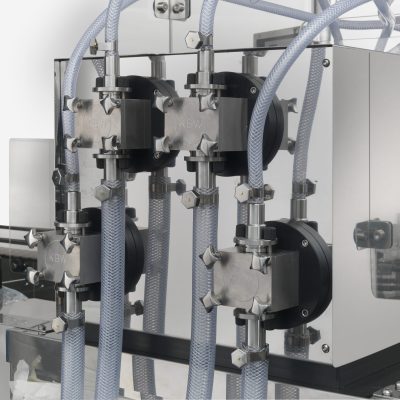

The number of containers or bottles to be filled per minute will need to be considered, to be able to understand which liquid filling machine will be suitable for your production. Most semi-automatic single head machines can offer up to 20 containers or bottles per minute, but a semi-automatic twin head liquid filling machine may be required to achieve higher production rates of up to 35 containers or bottles per minute. If filling rates need to be anywhere from up to 60 containers or bottles per minute all the way through to up to 150 containers or bottles per minute then a fully automatic liquid filling machine with either four heads, six heads, eight heads, ten heads or even twelve heads may be more suitable.

Whatever your liquid filling needs are, KBW Packaging can help you find the liquid filling system, or systems, that best suit your production needs. We have an experienced and knowledgeable Technical Sales Department available to help advise and support you from the project start to installation and beyond. You can reach us easily on 0044 (0)1252 322220 or for via email click here.