Main Differences Between Gear Pump, Peristaltic Pump, and Piston Pump Filling

When it comes to liquid filling processes, choosing the right type of pump is crucial. Gear pumps, peristaltic pumps, and piston pumps are three commonly used options, each offering unique advantages and applications. Understanding their key differences can help industries optimize efficiency, accuracy, and maintenance costs. Below, we explore the core distinctions between these pumps to help you make an informed decision.

1. Gear Pump Filling

Gear pumps operate using rotating gears to create a consistent flow of liquid. They are best suited for handling viscous fluids, such as oils, syrups, and certain chemicals.

Advantages:

- Provides a continuous and steady flow, making it ideal for high-volume applications.

- Capable of handling both low and high-viscosity liquids efficiently.

- Requires minimal maintenance due to fewer moving parts.

Disadvantages:

- Not ideal for shear-sensitive liquids, as the rotating gears may degrade the product.

- Limited precision compared to piston and peristaltic pumps.

- Can experience leakage if seals and gears wear out over time.

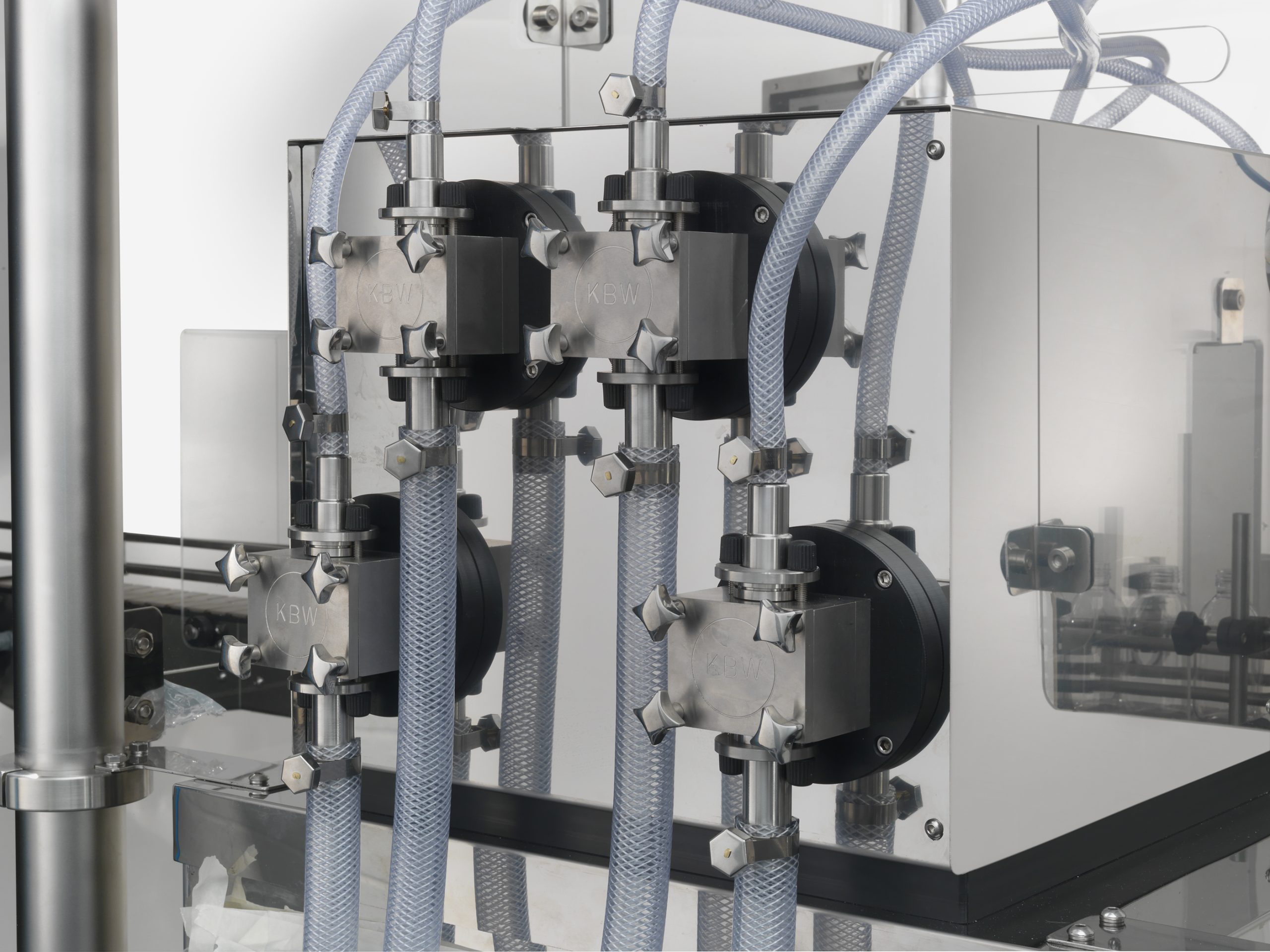

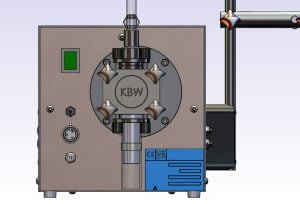

2. Peristaltic Pump Filling

A peristaltic pump, also known as a tube pump, functions by compressing and relaxing a flexible tube, pushing liquid forward. This makes it a contamination-free and highly precise option for sensitive applications.

Advantages:

- Excellent for sterile and hygienic applications, such as pharmaceutical and food industries.

- Ensures zero contamination since the liquid only contacts the tube.

- Highly precise dosing with minimal product loss.

Disadvantages:

- Tubes require frequent replacement, increasing maintenance costs.

- Limited to low and medium-viscosity fluids.

- Slower flow rates compared to gear and piston pumps.

3. Piston Pump Filling

Piston pumps work by using a piston mechanism to draw and dispense a specific volume of liquid. They are widely used in industries requiring high accuracy and consistent filling volumes.

Advantages:

- Provides high precision and repeatability, making it ideal for pharmaceutical and cosmetic industries.

- Suitable for both high and low-viscosity liquids.

- Can handle products with particulates, making it versatile for food processing.

Disadvantages:

- More complex in design, requiring regular maintenance.

- Typically higher upfront cost compared to peristaltic and gear pumps.

- Mechanical wear can impact long-term efficiency if not maintained properly.

Key Differences and Best Use Cases

| Feature | Gear Pump | Peristaltic Pump | Piston Pump |

|---|---|---|---|

| Flow Type | Continuous | Pulsating | Precise, controlled |

| Best For | High-volume, viscous fluids | Sterile, contamination-free applications | Highly accurate dosing |

| Maintenance | Low | High (frequent tube changes) | Medium (requires calibration) |

| Precision | Moderate | High | Very High |

| Suitable Industries | Chemical, automotive, industrial,

Cosmetic |

Pharmaceutical, food, biotech | Cosmetic, medical, food processing |

Choosing the Right Pump for Your Needs

If you need a pump for high-volume and viscous liquid filling, a gear pump is an excellent choice. For industries that prioritize sterility and minimal contamination, a peristaltic pump is the best option. On the other hand, if precision and versatility are your top concerns, a piston pump will offer the most reliable performance.

By considering the nature of your liquid, desired accuracy, and maintenance requirements, you can select the best pump for your application. Making the right choice will not only improve efficiency but also reduce costs and ensure a seamless production process.

Final Thoughts

Selecting between a gear pump, peristaltic pump, and piston pump depends on various factors Each pump has its own strengths and limitations, so understanding these differences will help you optimize your filling process effectively. Whether you need high-speed continuous flow, sterility, or pinpoint accuracy, there is a perfect pump for your industry’s needs.